NEWS

How is the rigid paper tube made?

How is the rigid paper tube constructed to match your product?

Structure of hard paper tube (carton paper tube)

Hard paper tube is also known as carton paper tube – a familiar packaging material, especially in industries. Widely applied to different industries, therefore, the structure and specifications of hard paper tubes for each industry are also completely different.

Called one of the products in the packaging, but the hard paper tube is not used to wrap the product from the outside, but is used to fix and shape the product from the inside – just as the name “paper core”. ” or “paper tube” in the manufacturing industry is also known as “bore tube”.

In particular, the core of a large carton can also be used to wrap the outside of the packaged product, in this case, the hard paper tube becomes a round carton – this is a preferred type of packaging box. high in export and transport due to the more optimal cylindrical properties in protective packaging. Sao Do specializes in manufacturing export standard round cartons in the most demanding markets such as Europe & America.

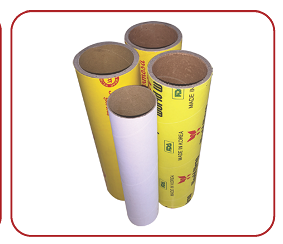

Hard paper tubes of various sizes

The main material to make the core of the hard paper tube is Kraft paper (Medium paper) combined with specialized glues, under the tight pressure from the core wrapping machine to make the carton paper tube.

Depending on the purpose of use and the object of the product to get the right hard paper core in terms of size, thickness as well as pressure resistance.

Cardboard paper tube core is round, long and used for a variety of purposes

Technical requirements of rigid paper tube (carton paper tube)

Pressure resistance (stiffness) is one of the most important factors in the quality of a rigid paper tube. Paper tubes used for each product, each industry will have a certain hardness. High or low hardness depends on the purpose of the customer’s product application. For products with high wrapping, tightening, of course, the hardness of the paper core will have to be compatible.

If you use a paper core with a thickness that is too thin, the hardness is not suitable for the tightening force, it will cause distortion and creaking of the paper core. This will seriously affect the quality of your product, because if the paper core is not quality, the product will slip out of the fixed roll.

Cardboard paper tube structure

Think about it, if you use a paper core of poor quality in terms of stiffness to wrap a spool (or cloth) product, when the paper core is flattened inwards because the tightening force is too high, it will cause the whole spool (reel) to be slip out of the fixed reel, tangling or even damaging the entire product. Fixing this problem will take a lot of time, effort and quite expensive – sometimes even more than the cost of buying a quality paper core.

Just a small detail about the paper core will affect many related issues and the reputation of the business, so it is very important to ensure product quality in general and the hardness of the paper core in particular. necessary that companies and businesses must always pay attention to.

The most typical example is the core for steel coil, if the core quality of the steel coil is not satisfactory, it can damage the steel coil up to 3000usd/roll while the cost for the core is only a few hundred thousand dong.

The core of the coiled paper tube must meet the hardness standard

Various applications of rigid paper tubes (carton paper tubes):

Paper industry: Toilet paper rolls, fax rolls, telephone rolls, printing paper, etc.

Packaging manufacturing industry: Core tape rolls, PE, PP, PVC shrink film rolls

Textile industry: Thread core, fabric reel, carpet roll or as a stand for POY, DTY winding.

Steel industry: Steel coil core, corrugated iron core, aluminum coil, stainless steel, …

In other industries: Heat pipes, electric cores, civil construction, drain pipes; industrial pyro cores and tubular containers such as tea and coffee boxes.

Red Star manufactures and supplies hard paper tubes (carton paper tubes)

Sao Do specializes in manufacturing and supplying solid paper tube cores in large quantities and in various specifications. Currently, we are supplying paper cores for steel coils at leading steel companies in Vietnam with high tightening strength of steel coils weighing 3 tons, 5 tons, 7 tons, 9 tons, …

In particular, Sao Do’s paper core products are always tested for quality for pressure resistance (hardness) before mass production and handing over to customers. Therefore, you can be completely assured of the quality of the hard paper core products we provide.

For more information about the price list of paper braces, please contact:

VIETNAM STARS INDUSTRIAL CO., LTD

Address: D2 Street – Zone D – Pho Noi A Industrial Park – Lac Hong Commune – Van Lam District – Hung Yen

Phone: 093 6464 222

Email: info@redstarvn.com

Website: redstarvn.com